Our attention is now drawn to the problem of data communications in the industrial environment. This is the problem of data communications in the manufacturing facility. It is the problem of data communications on the factory floor or in the process control plant. Data communications in these premises can significantly benefit by using fiber optic cable as the Transmission Medium.

Let us begin by describing the industrial environment from a data communications perspective.

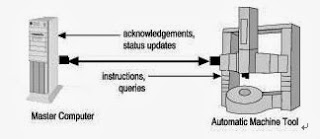

What type of data communications is going on here? Typically, the situation is illustrated in Figure 1-1. There is a Master Computer located somewhere in the manufacturing facility. In the past this was usually a mini-computer. Presently, it is either a workstation or PC. The Master Computer is communicating with any of a number of data devices. For example, it may be controlling automated tools and sensors. It may also be exercising control by querying and receiving data from different monitors. These data devices are located throughout the facility. The illustration provided by Figure 1-1 shows a machine tool, but in actuality the number of different automated tool types, sensors and monitors may be very large. By way of example, it may extend to well over 100 in a semiconductor fabrication facility.

The control procedure exercised by the Master Computer usually consists of sending a message out and receiving a message back. It may be sending automated tool or sensor an instruction. It may then receive back either an acknowledgement of instruction receipt or a status update of some sort. In like manner, the Master Computer may send queries to a monitor and receive back status updates.

Figure 1-1: Data

Communications in the industrial environment

As is readily evident, the whole control procedure is executed using data communications with appropriate signaling devices (modems) and other needed equipment located at both the Master Computer and the data device locations. Required data transmission rates need not be significantly large. On the other hand, in the industrial environment reliability requirements are quite stringent. This is so regardless of whether reliability is measured by either BER or link up-time or some other parameter. The consequences of an unreliable data communications link may be a mere annoyance when it comes to office communications. However, consequences may be catastrophic in a manufacturing operation. Literally, an unreliable link could close down a whole plant.

Generally, the type of situation described above leads the data communications in the industrial environment to follow an inherently hierarchical architecture. This type of architecture is shown in Figure 1-2. The Master Computer is located near a communications closet. The modems and/or other communications equipment (e.g., surge suppressors, isolators, interface converters) needed by the Master Computer to effect links to the data devices are usually rack-mounted in a card cage placed in the communications closet. Cabling then extends out from the card cage to the individual data devices. At the data device end the matching communications equipment may either be stand-alone or DIN Rail mounted. With the latter, the communications equipment snap onto a rail mounted on a wall or mounted on some convenient cabinet near the data device. DIN Rail mounting will be discussed in greater detail toward the end of this chapter.

Figure 1-2: Data

communications architecture usually found in the industrial environment

It is important to note that this is the general case not the absolute case. If the Master Computer has just 1 or a few ports there may be no need for a card cage. All data communications equipment may then be of the stand-alone type.

There are several topologies associated with this type of hierarchical architecture. The topology could be a star with a cable extending out from the card cage hub to each data device. Each ray of the star is simultaneously operating as data communications link. The topology could be a multi-dropped daisy chain, using the RS-485 interface standard. This is particularly suited to a polling, query-response, data communications scheme - the type of communications being carried out by the Master Computer. The topology could even be a broadcast bus, the type used by an Ethernet LAN.